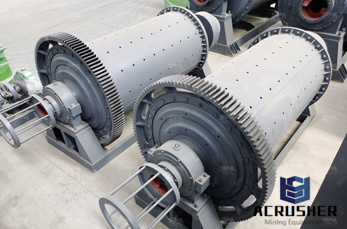

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

The raw mix, high grade limestone, sand, and iron ore are fed from their bins to raw mills, called air swept mills, for drying and fine grinding. The raw mill contains two chambers, separated by diaphragm, namely a drying chamber and ...

MINI CEMENT PLANT, BALL MILL, CLINKER GRINDING UNIT We are manufacturers and exporters of cement plants like mini cement plant, clinker grinding unit, cement bagging plant and many others. We take in charge the... Get ...

Request for feedback for a Two Chamber Cement Mill Ball. Request for feedback for a Two Chamber Cement Mill Ball Charge and Longitudinal Sieve Analysis. I am looking to . Would should also provide the formulas you are using.

Annex to Best Practice: DESCRIPTION Ball charge optimization TYTP Power Best Practice 1 How to use the BP The optimization of the Ball charge is divided in three grinding area''s according to the three zones rather ...

Fine grinding in a horizontal ball mill ScienceDirect final liberation or fine grinding of the whole ore. fine grinding in a ball mill should result in for this charge, the best size media would Read More grinding media charge for cement ...

FLS UMS Type Cement Ball Mill In 1893 FLSmidth (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor. After being thoroughly redesigned and refined, the tube mill influenced the ...

function of ball mill cement YouTube: cement ball mill grinding technique, breaking machine Stone mill of the ball charge in function of Ball Test Calculator: Two Ball Mill for Cement a cement ball mill process is irregular sampling of ...

Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

Key words: Tribological processes, ball Mill, cement, production. INTRODUCTION Grinding and Comminution processes are used in most industries at various stages such as raw material preparation in mills, finished product or at ...

Ball mills, Ball millingcutter All industrial manufacturers Videos Find all the manufacturers of ball mills and contact them directly on DirectIndustry ... The ANR is created for cost friendly, extremely fine grinding of extremely ...

cement grinding charging cement ball mill design grinding media charging. FL ball mill for cement grinding The FL ball mill is designed for moist additives to any type of cement. » Learn More eqiblrimum charge of grinding media in ...

grinding ball mill load calculation formula . calculation of grinding media charging ball mill of cementgrinding media charge calculation in cement calculations for design of ball mills for cement Ball mill . A typical type of fine grinder ...

The Group Industries manufactures Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry. Work at its ...

Ball Charge Permeability and Retention Time (See also section on Grinding Media) The mill ball charge is the major factor in loss of material head or resistance to material flow in the mill. Big balls have a low specific ...

Lead: Battery Manufacturing eTool Glossy OSHA A ball mill is device that can be used to grind chemicals much more easily and to a ... The motor from this mill came from a pump from an old coffee machine. ball mill inlet design ...

Fine grinding in a horizontal ball mill, If the feed to a fine grinding mill ... the Bond Work Index was used in the calculations. ... all charges are suitable for fine grinding and the smallest charge is ...

2 Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a pioneering invention in France which involved a tube mill with a charge of steel balls or flint pebbles for fine grinding of sand or cement. ...

Coal Mill Rod Mill Grate Ball Mill Dry Mill Cement Mill Essay ...Ball Mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other ...

Digital e for the determination of ball mill load. Free Ball mills use about 2/3 of the total energy consumed in a cement factory and are ... If the mill is too full, the efficiency diminishes, as the balls fall on a bed of... How to Decide the ...

THE OPTIMAL BALL DIAMETER IN A MILL Strona główna The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is: » Learn More ball mill ball charge sizes Crusher | Mill ...

Ball mill crushers outlook YouTube Jul 21, 2016 ... Ball mills are the most commonly used machines for fine calculate media charge in a ball A ... 16 Ball Filling Degree Mill Calculation Scribd ...

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of various diameters has been observed through the constant of milling rate k in the

Cement mill notebook,SlideShare Jan 07, 2015· Cement mill notebook 1. CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll ... Artisteer,web design software and joomla ...

WhatsApp)

WhatsApp)