The structural design of the SAG mill allowed for a ball charge filling of ... the mill has been ground out to confirm the actual filling. SAG mill ... (kW) 12% Ball ...

ball mill filling kw Grinding Mill China. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding ...

Modelling and simulation of ball mill wear ResearchGate. In the mineral processing industry, ball mills are used to reduce ore from one size distribution to another.

· re BALL MILL POWER . Dear Sahu G. I have already written the mill dimensions like. *11m. 28% filling. 180t gr. media. rpm. mill installed kw .

Planetary Ball Mills. ... the grinding bowl filling is not just subject to the gravitational force as with traditional ball ... Function diagram of planetary ball mill.

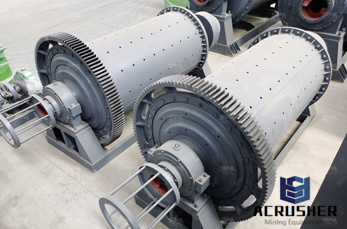

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

Mill Steel Charge Volume Calculation. ... We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that ...

Applying grindcurves to mill operation and optimisation ... low aspect SAG mill operated with a very high ball load in closed ... Mill filling, %

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... Figure Effect of mill filling on power draft for ball ... kW () Ld is the mean length ...

Ball mill is mainly used in the ore processing plant, which is the equipment to crush ores into pulp. The production process of grinding ball mill will affects the ...

ball mill grinding kw Pulverizer india. Autogenous mills, semiautogenous mills and ball mills for ... ball mill filling kw Grinding Mill China.

Ball Mill RETSCH powerful grinding and homogenization The High Energy Ball Mill Emax is an entirely new type of mill for high energy input.

Ball Mill Filling Kw.. ball filling ratio, and mill rotation speed on ... as well as ball mills with a drive power of up to 1000 kW ... The ball mill operates through ...

16 Ball Filling Degree Mill ... 4,640 [kW] motor shaft [kW] electr. counter [kWh/t] [cm²/J] [] [t] [kW] [kWh/t] [m] [m] [%] [t/m3] Filling ...

ball mill grinding kw. Autogenous mills, semiautogenous mills and ball mills for wet . SAG and ball mill for gold ore grinding. One of three SAG mills with m ...

BALL MILL: Costeffective steel tank where the balls rotation grant a high components crushing for a high quality final product. The machine is made with special ...

INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES TO THE GRINDING EFFICIENCY IN BALL MILLS Fatih DÖKME Şişecam Kimyasallar rubu Soda Sanayi .

Investigation on measuring the fill level of an industrial ball mill based ... It is concluded from Fig. 3 that the material filling ratio (the sum of the ball ...

Motor Sizing Determination leftpanel. 0. Mill Power, kW KiloWatts ... BALL MILL MOTORPOWER SIZING CALCULATION : Disclaimer Ready to reset.

kW). Feed size is usually ½ inch or less; ... The theoretical critical speed of a ball mill is the speed at which the centrifugal force is

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... Mill drive 5000 kW ... • Empty heights of both the chambers measured to calculate the ball charge, % filling .

Ball mill is a key equipment to recrush primary crushed materials. Ball mills are widely used in cement, silicate products, 52555 new building materials, refractory ...

MODELING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP ... The fraction of mill filling f L 2. ... kW 0 200 400 600 Calculated ballmill power draw from .

Raw Ball Mill Kw. ball mill calculation kw and rpm. ball mill calculation kw and rpm, pew series jaw crusher is born with innovative significance.

WhatsApp)

WhatsApp)